The role of physical security in protecting critical business flows

In recent years, the concept of corporate security has been radically transformed. Whereas physical protection used to be focused on factories, offices and corporate headquarters, today it is increasingly evident that operational vulnerability extends throughout the supply chain. For many companies, the supply chain represents the real beating heart of the business: it only takes one physical disruption to generate economic, reputational and production damage that is difficult to recover from.

In this scenario, physical security as applied to logistics and supply chain is no longer an exclusively technical issue, but a strategic issue that directly involves corporate CEOs, Security Managers and Risk Managers.

The tipping point: exposed and poorly protected supply chains

With globalization, the increasing complexity of flows and the outsourcing of many logistics services, companies today depend on:

- Intermodal transport by road, rail, ship or air

- transit or third-party warehouses

- External logistics, shipping and handling providers

- Temporary storage prior to final distribution

Each of these steps introduces physical vulnerabilities:

- Theft in transitofraw materials, components, or finished products

- Sabotage or tampering alongthe route

- Unauthorized access towarehouses or storage facilities

- Handling or substitution of goods

- Subtraction of sensitive data associated with deliveries or customers

- Local or regional logistical blockageslinkedto geopolitical events, social tensions, or criminal actions

In many cases, companies do not have full visibility into these points because responsibility is outsourced to external suppliers and subcontractors, with widely varying safety standards.

The real costs of physical supply chain disruptions

Several recent studies, including in the European and international arena (such as the BCI and Allianz Risk Barometer reports), show that supply chain risks are now among the top 3 concerns stated by CEOs and corporate boards.

The consequences of a physical accident along the supply chain can be:

- Production interruptions due to lack of materials

- Delivery delays with contractual penalties

- Loss of strategic customers due to logistical defaults

- Brand damage and loss of market confidence

- Litigation and insurance costs

A single critical event along the logistics cycle can have multimillion-dollar impacts.

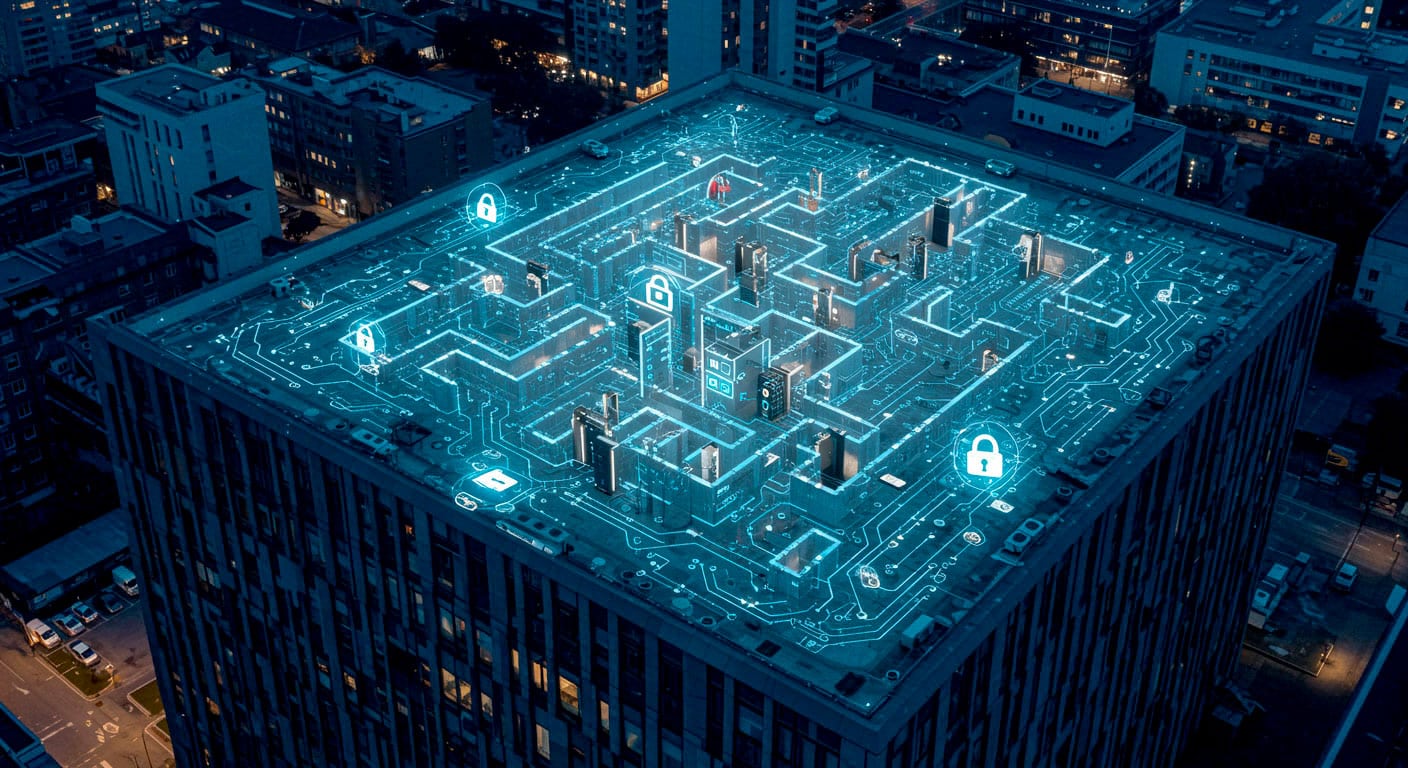

Where to intervene: map of physical vulnerabilities

To set up an effective security strategy along the supply chain, one must start with concrete mapping of critical points:

- Central depots and regional warehouses

- Loading/unloading points (especially in unmanned outdoor areas)

- Customs areas and intermodal transits

- Transport vehicles on the way

- Third-party sorting centers

- Physical access to logistics IT systems by outside personnel

Often, it is precisely at these points that the most sophisticated illicit actions lurk: theft for hire, document tampering, infiltration by unauthorized personnel.

Strategic countermeasures: how to protect physical logistics

There is no one-size-fits-all solution, but an integrated approach can significantly reduce risk:

- Specific security assessment on the supply chain, carried out by external and independent professionals

- Security audits on logistics and transportation providers

- Introduction of physical tracking, geolocation, and telemetry technologies on vehicles and containers

- Coordination with law enforcement and local authorities on sensitive routes

- Training of logistics personnel on active security procedures

- Periodic review of contractual security policies with external partners

The role of CEOs and security managers in the new governance of physical risk

CEOs and top management today must consider physical supply chain security an integral part of the business continuity plan.

- It is not just a technical or procurement issue.

- It directly impacts financial stability and the ability to maintain commitments to customers and markets.

- It becomes central to integrated enterprise risk management (ERM).

Security managers must also now work closely with operations, procurement, logistics and compliance, moving beyond the logic of “perimeter surveillance” and governing the entire physical business cycle.

Conclusion

In an economy where supply chains are increasingly interconnected and vulnerable, physical security cannot stop at corporate gates.

Protecting logistics, transportation, and warehouses today means protecting the core business.

Those who anticipate this scenario, by investing in an integrated security vision, will be able to manage crises, reduce damage, and ensure business resilience even at the most critical stages.